The Imminent Future of Parametric Nodes | N-AM 10

Project Brief.

Liaising between architect, façade engineer and manufacturer to achieve some middle ground where compromises are kept to a minimum will be an optimal step to grant a smooth transition from the design phase to the construction phase.

The power of parametric design is increasing, and the gap between design and construction is becoming bigger. A solution is needed to help to fill that gap and create a symbiotic relationship.

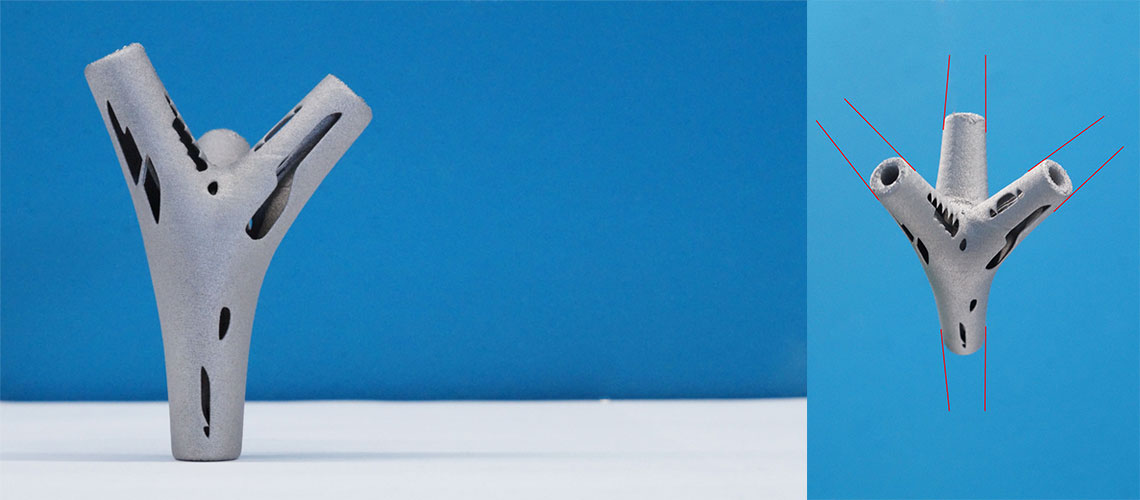

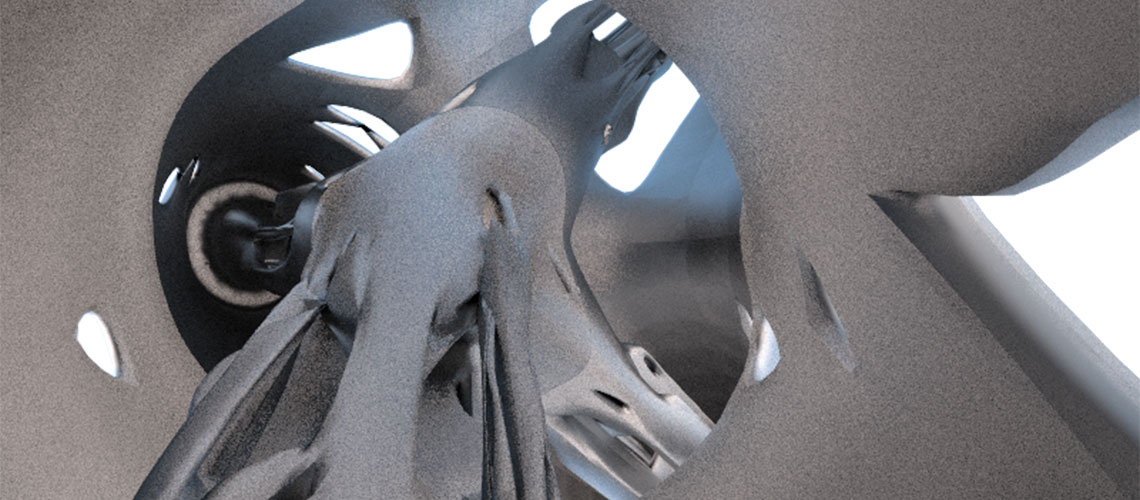

The search for a parametric node that can ease the process of façade construction is feasible but still needs to be developed from an idea to a product.

The limitation of offering a product with narrow possibilities is not agile in a world, where architects strive for innovative and unique designs.

Utilizing 3D printing is a powerful addition to fastening the process, but the high cost is still a barrier, as well extracting the nodes’ geometry as unique parts are not the best way to solve this dilemma. Any successful product needs to be standardized even to a certain extent to benefit from the advantage of cost reduction and could be seen as a norm.